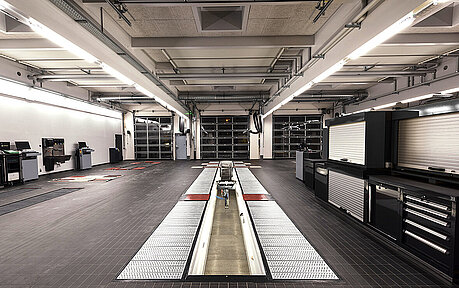

- One-piece prefabricated assembly pit with a filling chamber construction.

- Side wastewater channels to collect and dispose of dripping materials.

- A high degree of accuracy for headlamp setting positions and wheel alignment.

- Self-supporting filling chamber with honeycomb construction with integrated formwork and reinforcement.

- Various equipment features such as waste oil disposal systems, fresh oil supply, pit jacks, slide covers, brake test rigs and much more.

- Accessories are completely assembled, piped and wired at the factory according to consultation and planning.

- Project-based CAD planning.

- Installation time in max. 5 hours per system, thanks to the special assembly technology.

- Clearly defined construction interfaces.

- A specialist company according to WHG (Waste Water Act).

- Static tests of the prefabricated assembly pit with a filling chamber construction available.

- Meets waste water protection requirements according to WHG/VAwS (AwSV) / TRwS (779 / 785 / 786) and all specifications of DGUV 109.

- Approved, type-tested and certified by the German Institute for Building Technology (DIBt - No. Sec.-38.5-278).

- ISO 9001:2015 certified production facility.

- DIN EN 1090 certified production facility.

- Various patents have been granted.

- Top product quality.

- MADE in Germany

| Axle load: | 20 t |

| Live load: | according to SLW 60, DIN EN 1991-1-1:2010-12, DIN EN 1991-1-1 / NA:2010-12, DIN technical report 101:2009-03 and DIN 4085 supplementary sheet 1:2011-12. |

| Length: | according to customer requirements |

| Inner width: | 1.02 m i.L. |

| External width: | 3.10 m |

| Working width: | 1.62 m i.L. |

| Standing height: | according to customer requirements |

Integrated drainage system for the disposal of the lateral wastewater channels via the existing pump sump or gully. All connections are provided in accordance with the planning for electrics, compressed air, exhaust air, brake test rig, play detector and pit drainage. The prefabricated assembly pit has a double pit frame which means that slide covers, pit jacks, support bridges, etc. can be installed.

Accessories: examples include electrical installation, lighting, compressed air, exhaust air, brake test rig, pulldown assembly, play detector, pit jacks, support systems and much more.